|

|

| |

| |

| News - Metric featured in CNC West article. |

| October 25th, 2010 |

|

| Metric Machining deploys its new ERP system and CNC West talks about it in a recent article. |

| |

|

Make Parts, Not Paperwork

The New Management Team at a Successful Screw Machine Job Shop Uses Visual EstiTrack

to Totally Integrate Internal Systems from Quoting to Delivery.

Story and photos by C. H. Bush, editor

|

|

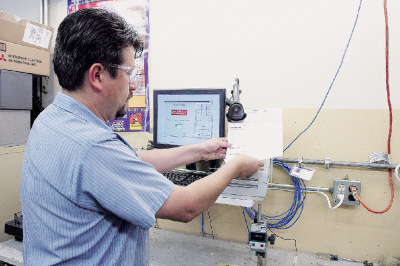

CNC leadman Rafael Quiroz uses a bar code scanner linked to a live Wyse terminal, which, in turn is linked to the company’s central server. Data goes into and comes from Visual EstiTrack which automatically tracks job costs, machining time, etc. The operators need only to enter the number of parts made, which significantly improves accuracy of job cost reports.

Okay, suppose you’re the number two person on a new management team assigned to get control of a very successful, 38-year-old screw machine job shop with 94 employees producing millions of parts a year. Also, suppose when you get there, you find that all the internal systems essentially use 1980’s technology, which means manually produced spreadsheets for quoting, job costing, tracking, reporting, inspection, packaging, shipping and customer relations. You discover that the reports you receive are full of errors or come in too late to help make timely decisions. What would you do?

|

|

The company? Ontario, CA’s Metric Machining, Inc. The management team? Dave Parker, new president and son of the company’s founders Richard and Joan Parker. Second man on the team is Tim Shuell, vp, who was asked by Parker to come in and help get things going 21st century style.

“That pretty well describes the situation we found when we took over the reins at Metric in October of last year,” says Shuell. “This company has an outstanding reputation in the industry. We make parts for some of the biggest names in the aerospace, agriculture, electronics, automotive and offroad vehicle industries. And what we found when we got here is probably typical of many older, well-established companies. You know, lots of loyal, hardworking people running around following systems that had been created long ago, but are now obsolete by current standards.”

Shuell, who has years of experience as an entrepreneur running his own business, in management at other screw machine companies, and as a business consultant, shakes his head a bit when he considers what was going on.

“Metric was very organized,” he says. “It had systems, but none of them really took advantage of today’s technology. For instance, on the quoting side. You had a spreadsheet that could only capture a limited amount of information and had to be manually transferred to the manufacturing software. The more manual transfers required, the more your exposure to human input errors.” The whole system was very labor intensive, Shuell says.

“The old spreadsheet quotes did not prevent the company from getting orders,” he explains. “But none of the information on the quote sheet was in the orders, so it had to be translated manually onto a router for making the parts in the shop. Just to process an outside purchase, a P.O. had to be created. The paperwork had to be checked by another person, and then put in a box and transported to another person upstairs. That was entered into the system by still another person whenever a bill came in and verified by yet another person. Travelers, POs for materials, inspection reports, all were created manually. On and on.”

Altogether, Shuell says there were seventeen or more different pieces of paper manually generated just for one job. “All those pieces of paper had to be printed, transported, filed or tracked just to get a job done,” Shuell explains. “If the people hadn’t been very conscientious and hard working, no telling how many jobs or customers might have been lost over the years. It was really the people who made the system work at all.”

|

|

Enter 21st Century Technology

Shuell had been involved with and solved such problems before as part of his previous life as a consultant. As a result, he didn’t have to go on a major search to find a software package to meet their needs. He already had the answer right at his fingertips.

“I had experience with several ERP software systems that attempted to integrate the data collection and work flow through a shop,” he says, “but the one that impressed me most was a package called Visual EstiTrack from Henning Industrial Software, Inc. I liked it for several reasons. First, it seemed to be written by programmers who had first hand knowledge of machine shops and maufacturing. Second, I knew it was a completely integrated shop management system that offered everything we needed, including estimating, sales orders, shop orders, time collection, job costing, scheduling, inventory management purchasing, receiving, shipping, and invoicing, , all at a very competitive price. When I recommended it to Dave Parker, he said, ‘Let’s do it.’ So, we installed twenty seats.”

|

|

Metric president David Parker, left, and vp Tim Shuell discuss

their new workbench design in the quality control department.

The new system puts Visual EstiTrack monitors with everything

inspectors need immediately available and eliminates the need

to go to file cabinets to get prints and quality documents

Visual EstiTrack

Shuell and Parker went all the way with their

installation of Visual EstiTrack. “I had seen the

system used in the past but never with the integrated

accounting package.” says Shuell. “We decided,

however, to fully integrate all our systems from

quoting to job costing, production control, inspection, inventory, purchasing, billing, shipping and reports

to our customers.

|

|

We’re using everything the software can deliver, and the results have been amazing. Just the benefits of getting things done so much faster has paid for the software. Our quotes are faster and more accurate. We’re getting more orders. Everything we do is faster and more accurate, even in our inspection department.”

|

|

How did the system speed up inspection?

“It slashed the amount of paperwork required,” Shuell explains. “The amount of paper required just to get started inspecting was substantial. Inspectors constantly had to go into the cabinets to look up things. They did a lot of walking back and forth. Now all the data is right in front them on their Visual EstiTrack screens. As a result we were able to reallocate some of our staff. Now we have two inspectors doing more than four did previously. We made some other changes to the department, too, like going from desks to workbenches, but we couldn’t have done any of that without the software.”

|

|

Installation No Problem

The Visual EstiTrack system went live at Metric on October 25, 2010.

“The Hennings people first asked us in detail what we wanted to do with the system,” says Shuell. “We told them, and then they gave us a detailed list of things we would need to do to prepare for the installation. Probably our biggest challenge came because of the bilingual nature of a lot of our employees. We had to rely on a lot of our people to help us translate during the training. We took each department aside, walked them through what we were trying to do and how important it was. Everyone responded very well. They all like the system, because it reduces the amount of work they have to do. The bottom line is Henning has fantastic customer service. They made what might have been a very difficult process about as painless as possible.”

Another reason Visual EstiTrack is so effective, is because the Hennings people hold annual conferences to ask their customer what needs to be repaired or improved, Shuell says.

“No matter how long you use this software, I don’t think you can ever find an end to the features that are in it,” he says. “I’ve used it for almost eight years, and I’m still finding new things in it. It’s just blows your mind sometimes.” And what about those 17 pieces of paper?

“Only four of those are left,” Shuell says, “and none of those are prepared by hand. Nowadays we make parts, not paperwork.”

|

|

|

|